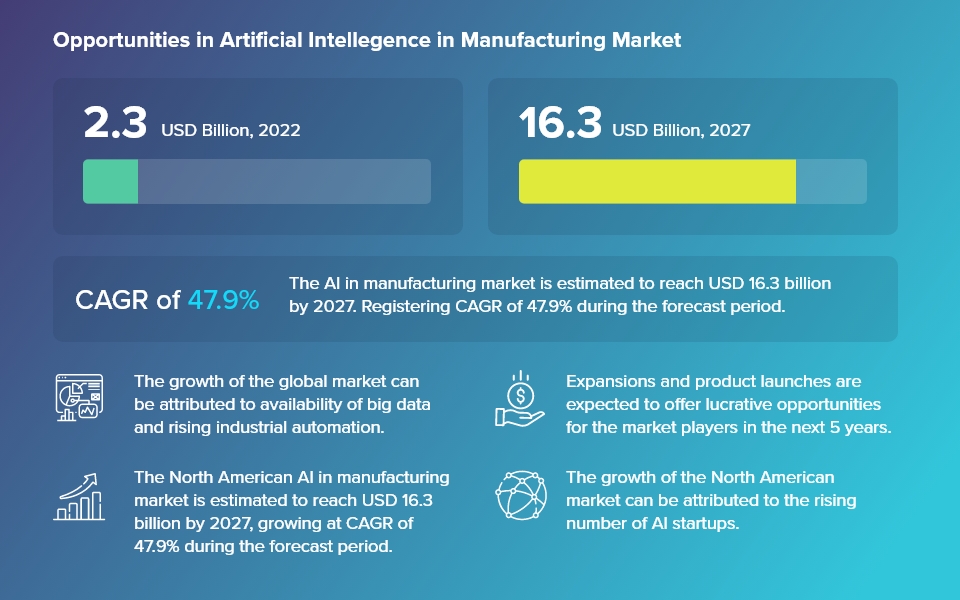

According to a report by Markets and Markets, Artificial Intelligence in manufacturing market size is valued at USD 2.3 billion in 2022 and is anticipated to USD 16.3 billion by 2027; growing at a CAGR of 47.9% from 2022 to 2027.

The opportunities for the AI in manufacturing market include :

- Improvements in the operational efficiency of manufacturing plants

- Rising application of AI in intelligent business processes

- Growing adoption of automation technologies

However, the reluctance among manufacturers to adopt AI-based technologies is expected to restrain the market growth. However few critical challenges faced by the market players are due to the limited availability of skilled workforce & concerns around data privacy.

IOT – A Driving factor for AI in Manufacturing

Industrial Internet of Things (IIoT) is making industrial processes efficient, productive, and innovative by providing real-time information about operational and business systems. The data that is derived from the IoT devices are converted into instructions that would instruct machines to perform specific activities.

These instructions are designed by an AI system to learn human behavior through deep learning, context awareness, and natural language processing (NLP). AI-based systems take lesser time and can work continuously without error. As a result, manufacturing efficiency improves, which further helps in business growth.

Uses of Artificial Intelligence in Manufacturing

Computer Vision

AI and computer vision are facilitating production, logistics optimization, fleet management, and quality inspection. Machine vision can help to increase capacity and reduce transactions in logistics and warehouse areas. This can translate to the elimination of scanning needed by human employees or by making sure that customer orders are packed as accurately as possible.

Predictive Maintenance

Pinpointing potential errors and downtime by analyzing sensor data helps manufacturers to predict when machines will stop working and schedule maintenance before it happens. This leads to improved efficiency, as operations don’t need to stop, and to reduced costs from machines failing and needing to be replaced. Businesses can also automate visual inceptions with computer vision to save potential losses of up to 20% in annual sales.

Edge Analytics

Offering decentralized and fast insights from datasets, edge analytics collects data from sensors or machines. This data collected on the edge can then be analyzed and transformed into insights that can be used to optimize operations. Edge analytics can then help track employee health and safety, improve both production yield and quality and detect the beginning stages of performance deterioration and risk failure.

Robotics

Manufacturing robots are excellent to automate repetitive tasks and help eliminate human employee mistakes. From welding to product inspection these robots let employees shift their attention to other areas. And with computer vision, robots can accomplish precise operations.

Inventory Management

Due to their capacity for forecasting and planning supply, machine learning solutions can be used to predict results more accurately. This will enable businesses to manage their inventory by planning when products need to be replenished, offering more accurate arrival times for goods. AI can also create models to predict future demands based on existing inventory data.

Benefits of Artificial Intelligence in Manufacturing

Safety

Human employees are fallible – particularly when distracted or tired – which can lead to accidents and errors happening on a factory floor. AI can minimize, if not eliminate, the occurrence of accidents and errors. Having remote access control leads to a reduced need for human resources, and advanced sensors integrated with IIoT (Industrial Internet of Things) devices help make the installation of barriers more efficient.

Lower operational costs

Although potentially requiring costly capital investment, the ROI of adopting AI in manufacturing will increase with time. Predictive maintenance, for example, can greatly reduce the costs involved with downtime and broken machines. Machine learning and CAD, combined with advances in 3D printing and IIoT-connected devices, allow businesses to test products virtually and print a less costly prototype before the final version is mass-produced. This minimizes the costs involved with trial-and-error.

24/7 production

Unlike human employees, machines can work around the clock without needing sleep. This means the production line can be working 24/7, expanding the production capabilities to meet increasing customer demands. Machines are also more efficient in areas like assembly, reducing turn-around times.

Direct Automation

IoT devices integrate manufacturing processes alongside big data, making them programmable through a logic controller. This leads to data that is generated, recorded, and analyzed, covering all processes in production. When programmable logic controllers have an AI capacity for deep learning, they can automatically react to the data and take action in real-time without requiring human employees to intervene.

The Future of Artificial Intelligence in Manufacturing

Every manufacturer is aiming to look for new ways to save and make money, reduce risks, and improve overall production efficiency. This is crucial for their survival and to ensure a thriving, sustainable future. The key lies with the major 4th Industrial Revolution technologies, especially AI-based and ML-powered innovations.

According to McKinsey, companies using AI have witnessed cost savings and revenue growth. 16% of those surveyed noticed a 10-19% decrease in costs, whereas 18% saw a 6-10% increase in overall revenue.

Another McKinsey report also suggests that AI can improve forecasting accuracy in manufacturing by 10-20%, which translates to a 5% reduction in inventory costs and a 2-3% increase in revenues.

Manufacturers will continue to invest in technologies like AI and machine learning to further bring down production costs and improve time-to-market. In the aftermath of a global pandemic, manufacturers will strive to make their businesses more resilient by adopting technologies that automate tasks, forecast disruptions, and facilitate end-to-end control of all operations.

Talk to us at gleecus.com/contact-us