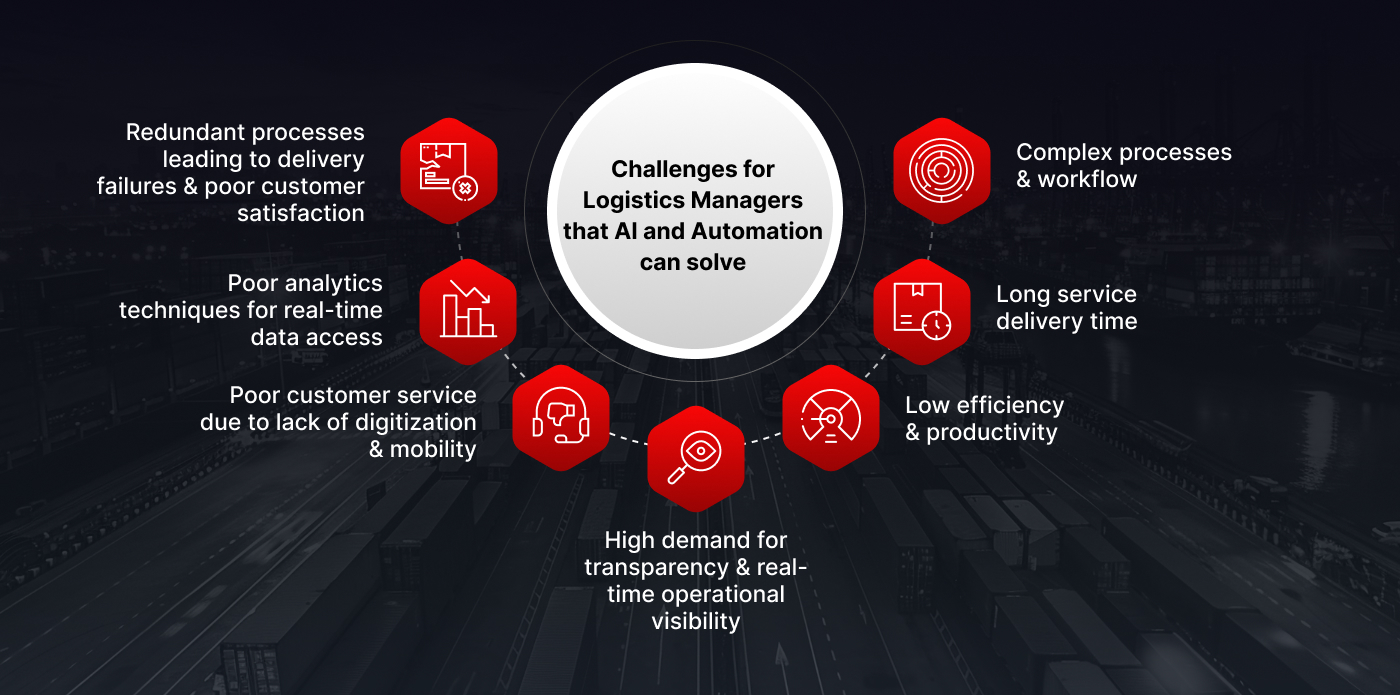

Traditional supply chain operations face several limitations in today’s competitive business landscape. There is a gap in transparency across the entire supply chain and all processes function as individual disjointed units. AI and automation bring in full scale visibility and dynamic decision making to the supply chain landscape.

Warehousing and Transportation

By leveraging AI and automation in warehousing and transportation, companies can streamline their supply chain operations, reduce costs, and improve customer satisfaction.

Smarter Routing Decisions

Traditional methods of route planning often rely on manual calculations and may not account for real-time traffic conditions, weather, or road conditions that can significantly impact delivery times. AI automates route planning with smarter routing decisions. AI-powered routing systems can:

- Optimize Routes: AI algorithms can analyze multiple routes and choose the fastest, most fuel-efficient route based on factors such as traffic, road conditions, and weather.

- Reduce Fuel Consumption: By minimizing unnecessary detours and optimizing routes, AI can help reduce fuel consumption and lower transportation costs.

- Improves Delivery Time: AI can predict traffic and adjust routes to bypass traffic jams ensuring timely deliveries and reducing the likelihood of late or missed deliveries.

- Dynamic Cross Docking: AI considers factors like traffic, weather pattern, delivery time to dynamically create routing plans. Monitoring yard activity in real-time reduces vehicle wait time. Optimizing the picking route ensures delivery of the product to the end customer in the shortest possible time.

Inventory and Movement

Inventory management of a warehouse can feel like a constant battle against stockouts, inefficient layouts, and picking errors. Here are some ways AI can enhance these processes:

- Automated Inventory Management: AI-powered systems can track inventory levels in real-time, alerting warehouse staff when stock is running low or when products need to be reordered. Saves you from scrambling for the last widget.

- Optimized Warehouse Layout: AI can analyze your current warehouse layouts and suggest improvements to maximize storage capacity and minimize movement of products. AI can analyze the fast-moving products in your warehouse and plan them to be placed near the exit for quicker check out.

- Automated Sorting and Picking: AI can help automate the sorting and picking processes, reducing errors and increasing efficiency. For manual pickers it can track picking routes and suggest the best path to reduce bottlenecks and optimize picking time.

- Packing: AI algorithms helps to categorize products based on size, weight, or fragility and make it easier for automatic packing by industrial robots. Depending on these factors they can also easily be sorted, picked, and transported across an automated sortation system.

Analytics

Analytics plays a crucial role in optimizing warehousing and transportation operations. AI-powered supply chain analytics tools process vast amounts of data collected from sensors, radio frequency identification tags, and IoT devices within the warehouse. They can help supply chain managers make data-driven decisions with valuable insights. Some key benefits of AI analytics in warehousing and transportation include:

- Predictive Maintenance: AI can analyze data from sensors and equipment to predict when maintenance is needed, reducing equipment failure and unplanned downtime and improving overall efficiency.

- Real-Time Monitoring: AI also monitors warehouse operations in real-time, detecting and addressing issues such as stockouts, overstocking, or damaged goods.

- Supply Chain Visibility: AI can provide a comprehensive view of the entire supply chain, enabling managers to track products from origin to destination and make informed decisions.

Manual Processes and Workflow

By leveraging AI and automation to streamline manual processes and workflows, companies can improve efficiency, reduce errors, and enhance overall supply chain performance.

Scan Events

One of the most time-consuming and error-prone tasks in warehousing is scanning products during receiving, put-away, and shipping. AI and automation can help streamline these processes:

- Automated Scanning: Traditional inventory data entry relies on handwritten timestamps in many cases. This process is prone to human error. AI-powered scanners can automatically detect and identify products, reducing the need for manual scanning and improving accuracy.

- Intelligent Routing: AI can analyze product information by scanning at every stage of a product’s journey and automatically route items to the appropriate storage location or shipping area, reducing manual handling.

- Exception Handling: AI can detect and flag exceptions, such as damaged or misplaced items, alerting warehouse staff for immediate action.

Appointment Scheduling

Scheduling appointments for pickups and deliveries can be a complex and time-consuming process. AI can help automate and optimize appointment scheduling:

- Real-Time Availability: AI can analyze real-time data on truck availability, driver schedules, and warehouse capacity to provide accurate appointment scheduling.

- Optimized Scheduling: AI algorithms can create optimized schedules that minimize wait times, reduce congestion, and ensure timely pickups and deliveries.

- Automated Notifications: AI can send automated notifications to drivers and warehouse staff about scheduled appointments, reducing the need for manual communication.

Track and Trace Technology

Tracking and tracing products throughout the supply chain is essential for ensuring visibility and accountability. AI-guided track and trace systems offer visibility of a product across the entire supply chain.

- Real-Time Tracking: AI-powered sensors and RFID tags can provide real-time tracking of products as they move through the supply chain, enabling immediate action in case of delays or disruptions.

- Predictive Analytics: AI can analyze historical data and current conditions to predict potential delays or disruptions, enabling proactive measures to mitigate their impact.

- Automated Reporting: AI can generate automated reports on product movements, providing valuable insights for supply chain managers and customers.

Personalized Customer Service

In the supply chain industry, providing personalized customer service is crucial for building strong relationships and ensuring customer satisfaction. By leveraging AI and automation in personalized customer service, companies can enhance their responsiveness, improve problem-solving capabilities, and build stronger, more loyal relationships with their customers.

Chatbots and Conversational AI

One of the most prominent ways AI can improve customer service is through chatbots and conversational AI. These technologies can:

- Provide 24/7 Availability: Chatbots can be available around the clock to address customer inquiries and concerns, ensuring prompt responses and improved customer experience.

- Personalized Interactions: Conversational AI can analyze customer data and preferences to provide personalized responses, making the interaction more engaging and tailored to the customer’s needs.

- Seamless Escalation: When a customer’s query requires human intervention, chatbots can seamlessly escalate the conversation to a live agent, providing a smooth transition and maintaining the context of the interaction.

Troubleshooting Issues

AI can also play a crucial role in helping customers troubleshoot issues related to their supply chain operations. By leveraging AI-powered systems, companies can:

- Automated Diagnostics: AI can analyze customer data and identify potential issues, providing step-by-step troubleshooting guidance to help customers resolve problems quickly.

- Predictive Maintenance: AI can monitor equipment and infrastructure, predicting potential failures and proactively alerting customers to take preventive measures, reducing the likelihood of disruptions.

- Remote Assistance: AI-powered remote assistance tools can enable customers to receive real-time support from experts, even in remote locations, without the need for on-site visits.

Research into Claims

When customers file claims or disputes, AI can assist in the research and resolution process:

- Automated Data Gathering: AI can quickly gather and analyze relevant data, such as shipping records, inventory logs, and customer communications, to build a comprehensive understanding of the claim.

- Intelligent Insights: AI can provide insights and recommendations based on the gathered data, helping customer service representatives make informed decisions on how to resolve the claim.

- Streamlined Workflows: AI can automate various steps in the claims research and resolution process, reducing the time and effort required to address customer concerns.

Conclusion

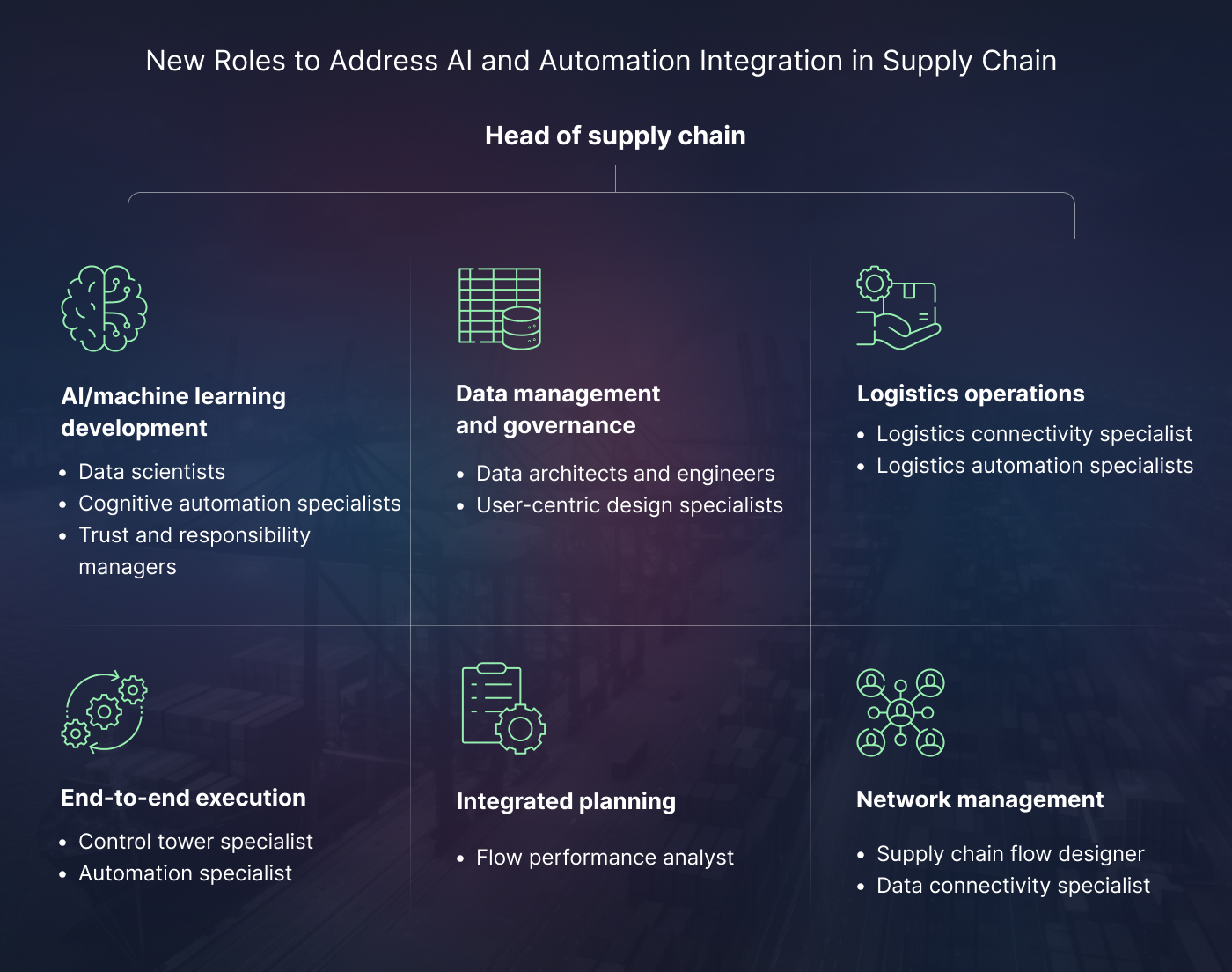

As supply chains become more complex, automation and AI are essential for staying ahead. Adopting these technologies requires new roles, like logistics automation specialists and data scientists. Upskilling existing staff can be challenging, so partnering with experts is a smart move. Gleecus TechLabs Inc. offers tailored AI-powered automation solutions for businesses of all sizes. Our Extended Team Model lets you hire experts in supply chain automation and other digital transformation technologies from a global pool of talents, ensuring your business navigates these complexities successfully.